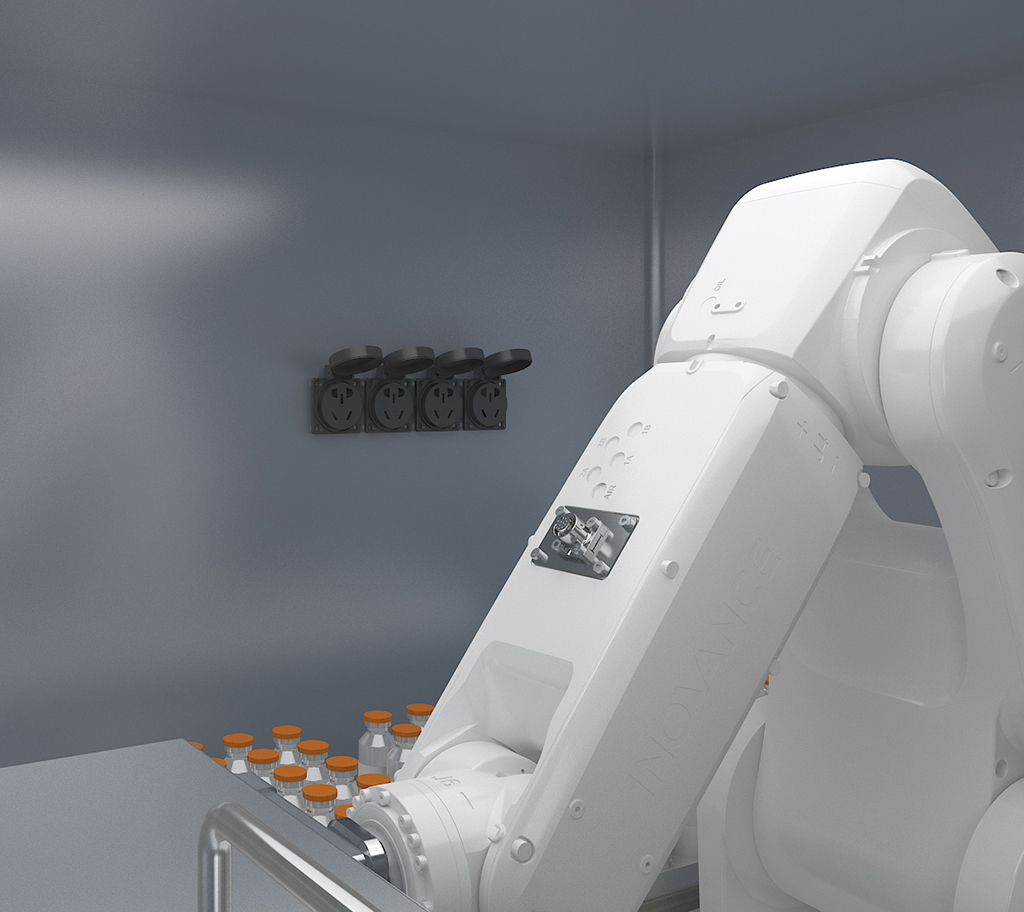

Smart automation equipment replaces manual operations, optimizing radiopharmaceutical production processes.

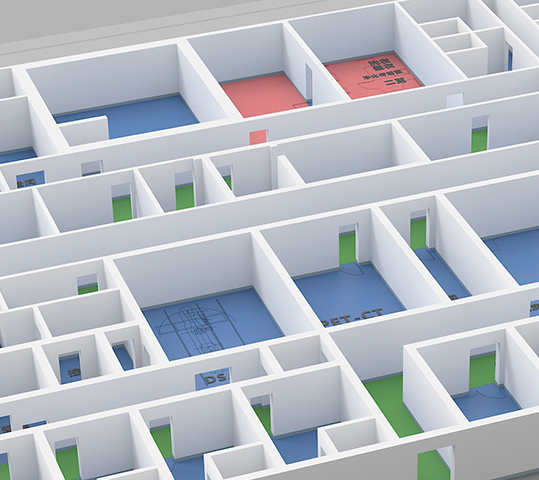

Smart automation equipment replaces manual operations, optimizing radiopharmaceutical production processes by enhancing precision, consistency, and safety. In radiopharmaceutical manufacturing, manual handling poses significant challenges due to radiation exposure risks, variability in product quality, and complex regulatory requirements. By integrating automated systems—such as robotic synthesis modules, automated quality control stations, and closed-loop dispensing units—production becomes more standardized, reproducible, and compliant with GMP regulations.

Automation reduces human error, shortens production cycles, and enables real-time monitoring and data logging, which are critical for ensuring product traceability and regulatory documentation. Furthermore, it enhances radiation safety by minimizing the need for direct human contact with radioactive materials. In high-throughput or just-in-time manufacturing settings, smart automation also enables scalable and flexible production, making it a cornerstone technology for the industrialization of next-generation radiopharmaceuticals.